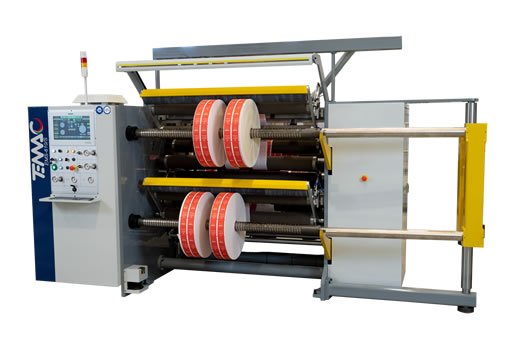

Dual – Shaft Slitter Rewinder EMS 610

The slitter rewinder mod. EMS 610/S has been projected as a Multi-Purpose Slitter and it is proposed as a “low cost” solution for users who still wish to focus on all technical Temac expertise and quality, maintaining the key features of our production’s output in terms of reliability and ability to work various types of material from plastic, laminates, paper to aluminium foils.

Also available in the EMS/IS model.

Contacts:

UK & Ireland: Stefano Nestri – +44 (0) 7547 114 153 – stefano.nestri@ukextrusion.com

USA & Canada: Maurilio Millefanti – +1 7065297317 – info@eurotechnical.net

Standard Equipments

Compact unwinding group “Shaftless” type.

Twin rewinding stations with fully clutched shafts with ball friction system to lock the cores during the rewound phase.

Twin slitting systems with oscillating magnetic razor blades and shear circular blades.

“Laser” core positioning system.

Side rewound roll unloading fork system.

Controls

All machine functions are managed by wide color “Touch Screen” unit able to store all machine parameters. This unit is able to save several machine menus which may be recalled from the operator.

A.C. asynchronous servo flux vector motors managed by last generation fully digital Inverters.

Options:

Independent “Shaftless” unwinding group with footboard or bridge web path.

Unwinding web tension control managed by A.C. asynchronous servo flux vector motor driven by fully digital Inverter.

Automatic shear circular blade units positioning system.

Special automatic and computerized system to control the weight of the lay on rolls used during the rewinding phase.

Automatic ended rolls “push out” system for top and bottom rewinding stations.

Automatic “Laser” core positioning system with computerized set up managed by “Touch Screen” unit

Technical data EMS 610 |

||

| Working width | mm | 1.000 – 1.300 – 1.600 |

| Max batch roll diameter | mm | 1.000 |

| Max rewound rolls diamenter | mm | 600 |

| Minimum slitting width | mm | 40 |

| Max axial displacement of batch roll | mm | +/- 50 |

| Max slitting speed | mt/min | 500 |