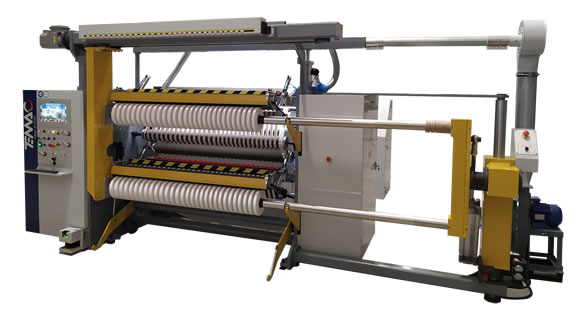

Eco-friendly slitter rewinder EMS/IS

Temac has recently introduced a revolutionary slitter rewinder for processing mater-bi films to the market, once again demonstrating its commitment to technological innovation. It’s based on the model EMS 610, but the new EMS/IS, a 3-motor machine, has definitively resolved issues related to cutting and finishing tubular master reels, thanks to a processing operation divided into several operational phases.

The versatility of the EMS/IS is one of its main strengths: in addition to effectively processing mater-bi film, the machine is designed to handle a wide range of materials, including plastic, composite materials, paper, and aluminum. This flexibility, combined with an excellent quality/price ratio, makes the EMS/IS a preferred choice for customers.

The innovative design of the EMS/IS includes servo motors and independent motors for each of its three units – unwinding, traction, and rewinding. The cutter can handle master reels with a diameter of up to 1000 mm, producing finished reels of 600 mm in diameter and a working width of 1600 mm, all while maintaining a speed of 600 m/min.

Outstanding Performance and Ecosystemac

A special system allows for saving and reusing energy, ensuring optimal performance under standard conditions. The outstanding performance and superior quality of the finished reels are guaranteed by the servo motor that regulates the different tensions in the unwinding and rewinding phases, thus also optimizing the processing of mater-bi reels. The machine management is entrusted to an industrial PC, offering endless customization possibilities and an intuitive, easy-to-use interface.

The system is prepared for remote connection, ensuring rapid and targeted technical assistance. Thanks to Ecosystemac technology, the EMS/IS cutter also stands out for its energy efficiency, making it one of the most economical machines to use and maintain on the market. With these features, Temac confirms its leadership in the sector, offering cutting-edge and high energy-efficient solutions.