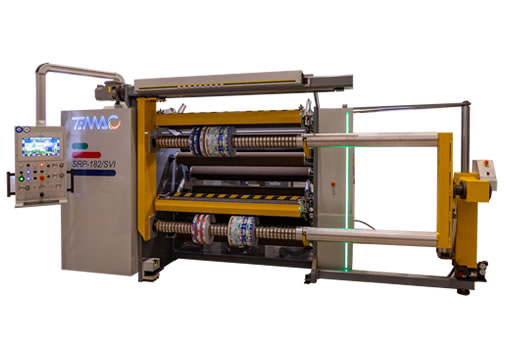

Slitter with top web passage path SRP 182

The new SRP 162/182/SVI series is proposed as “TOTAL GREEN” slitter rewinder thanks to an innovative electro-mechanical system for mother roll lifting. It fully belongs to the “Ecosystemac philosophy” because it has been projected as “TOTAL OIL FREE” machine, synonymous with high environmental compatibility and energy saving. Equipped with an independent vertical Shaftless unwinding group connected to the machine with top web path, SRP 162/SVI works optimally materials such as paper, aluminium, plastic films and laminates.

Standard Equipments

Standard Equipments

- Independent unwinding group “Shaftless” type.

- Twin rewinding stations with fully clutched shafts with ball friction system to lock the cores during the rewound phase.

- Asynchronous A.C. motors (digital flux vector inverters).

- Fully computerized system for the machine managing.

- Twin slitting systems with oscillating razor blades and shear circular blades.

- Special automatic and computerized system to control the weight of the lay on rolls used during the rewinding phase.

- Unloading side fork system.

Controls

Controls

Fully digital close flux vector inverter, high-efficiency and power-saving, manage all A.C. Asynchronous Motors.

PLC (programmable logic control with ETHERNET connexion “on board” for supervising and assisting remotely all the machine’s states) with human/machine interface managed by industrial Panel PC IP65 fan less (ASEM-ROCKWELL AUTOMATION), Touch-Screen 15.6”, 4GB Ram, Intel 2.0Ghz QuadCore with Windows10 IoT 64bit on SSD.

All machine controls are managed by wide colour “Touch Screen” unit.

Machine is able to store all work parameters as “work menus” for an extremely quick and sharp machine setting avoiding errors and downtime.

Automatic alignment system of the mother roll by edge guide group electro mechanic type with microprocessor, complete with CCD.

It is possible to control the machine by modem or Ethernet for a total remote control and direct service.

Options:

Unwinding web tension control managed by A.C. asynchronous servo vector motor driven by fully digital Inverter.

Automatic shear circular blade units positioning system.

Fully automatic “Laser” core positioning system driven by “Brushless” motor with computerized set up managed by “Touch Screen” unit.

Fully automatic ended rolls “push out” system for top and bottom rewinding stations.

Semi-automatic splice table group with air vacuum system with two independent vacuum plate (top and bottom) managed by PLC unit.

New anti-static bars with air ionization flow and electronic adjustable frequency control, supplied by low tension voltage.

Technical data SRP 182 |

||

| Working width | mm | 1.000-1.300-1.600-1.800-2.000 |

| Max batch roll diameter | mm | 1.000-1.200-1.500 |

| Max rewound roll diameter | mm | 820 |

| Minimum slitting width | mm | 20 |

| Max axial displacement of batch roll | mt/min | +/-50 |

| Max slitting speed | mt/min | 800 |