+39 0331661204 info@temac.it

For more than twenty years we have dedicated ourselves with passion and professionalism to the production of slitter rewinders and special machines on request, for the converting and packaging industry. These machines are used in the converting industry to process various types of flexible materials, from film to paper to laminates.

The main purpose of the slitter rewinders is to cut a large reel, for example of film, into smaller reels. A slitter rewinder consists of three main groups: the unwinder group, the cutting group and the rewinder group. A large reel, also called mother reel, is inserted into the unwinding unit, is unwound and cut into smaller reels to the desired size and then rewound.

There are different types of cutters and our main goal is to help our customers make the right choice based on their real needs.

We can focus the choice based on the size of the reel diameters, applications, performance, etc. Let’s choose together which are the most important parameters and find the solution that “fits perfectly”. We recommend that you visit the applications page for more tips.

Our machines are manufactured with a high level of automation resulting in ease of use: we ensure maximum performance with the best of technology.

We use management software that reduces machine downtime and ensures ever higher levels of performance. Thanks to the new “smartech” interface, our slitters are “4.0 ready” machines: the use of a PC opens up infinite possibilities for interactivity and connection with external environments, a true interface to comply with industry 4.0 directives without having to use hardware and software add-ons to make two different languages communicate, machine data can be transferred to customer management systems for statistical analysis and more. Electrical diagrams, technical drawings and manuals are on the PC “at a glance”

We adopt small expedients that are of great help to machine operators.

All cutters, if only the main technical parameters are considered, look the same, but it’s the details that make the difference. In our case, the starting point is always the customer and in particular the machine operator of the cutting department. It is by listening to the end users, those who use the cutter every day, that in the course of our experience, we have improved some aspects, introduced simple but decisive details, to meet their needs. And so each cutter is enriched with ad hoc solutions, so much so that each one has particularities, which make it unique.

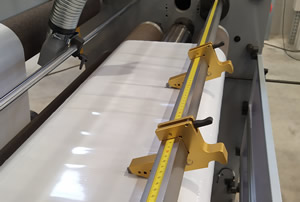

Our blade cutting system is completely tool free for simple and quick knife setting

Our photocell holder square bar is MOTORIZED with servo center with precision ADJUSTMENT that can be performed by the operator directly from the control panel

The circular cutting system is moved by a mechanical system for independent descent and translation of the cutting unit with centesimal adjustment. For operators who can first lower the blades positioning them with precision in the center of the groove and then move them by an identical thrust force

We offer simple solutions and help the operator to facilitate the setting of circular blades

Via Gasparoli, 182

21012 Cassano Magnago

(VARESE) – Italy

Mail: info@temac.it

Phone +39 0331661204

Fax +39 0331667292

VAT IT02514340120

REA: Varese N. 264017

Privacy / Cookies

Temac, sensitive to the themes of ecology, respects the environment with machines and cutters with low energy consumption.

Copyright 2020 Temac Srl | All Rights Reserved

To provide the best experiences, we use technologies such as cookies to store and/or access device information. Consent to these technologies will allow us to process data such as your browsing behavior or unique IDs on this site. Not consenting or withdrawing consent may adversely affect some features and functions.