Reliable and flexible slitter rewinders with upgrades and implementations

Owning a Temac slitter rewinder means always keeping the door open to the option of implementing upgrades without replacing the machine.

This flexibility is highly appreciated by all our customers and proves to be a major added value, especially in times of economic uncertainty like the current ones: carrying out an upgrade, replacing an obsolete component with its latest version, or integrating additional systems, even external to the slitter rewinder, is not a problem.

Accessories and customized modifications

Lately we have been handling many upgrade requests on somewhat older slitter rewinders, machines that already have several years of work behind them but are still perfectly functional and meet their owners’ expectations, often running three shifts, 7 days a week.

In these cases, the customer does not need to replace the machine, so they ask for the possibility to add an accessory that, over time, they have come to realize is needed.

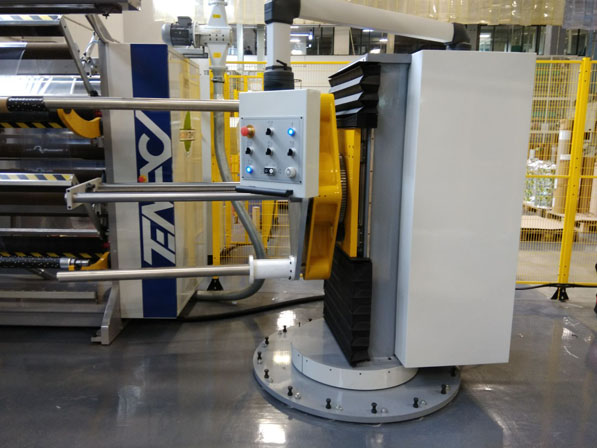

Sometimes it is simply a matter of adding antistatic bars, which were not originally included, as happened with a Greek customer just a few months after delivery and commissioning of the slitter rewinder. Other times it involves replacing the basic model of the side unloading unit with a more advanced one that reduces operator effort during roll unloading, as in the case of a Hungarian customer who chose this upgrade after purchasing a used Temac slitter rewinder.

These are all modifications that can be carried out without any particular issues: not from a design standpoint (Temac machines are flexible), not from a mechanical standpoint (the machines are often already prepared), and not from an electrical standpoint either. Signal exchange, data transfer, and the machine software obviously need to be updated as well, but generally the desired result is achieved within just a few days.

Integration of new systems per aggiornare le taglierine

We are also sometimes asked to implement a cutting system. This happens when a customer buys the slitter rewinder to slit and rewind certain types of plastic materials, flexible but non-stretch films, for which a razor-blade cut is sufficient, and after some time (even years) they also need to cut, for example, paper, which requires mechanical shear slitting with circular knives.

TEMAC intelligently designs slitter rewinders so they are already prepared for circular-knife slitting. This means that, at the design stage, the possibility of adding a circular-knife cutting system in the future is built in, should the need arise. Designing the slitter rewinder with provision for a future addition does not involve any extra cost for the customer; it simply keeps the option open. When circular knives are needed later on, the customer only has to purchase the required kit and request installation from us.

Other cases involve customers asking to install third-party systems on the slitter rewinder to optimize processing time by adding other operations, such as roll inspection, or material perforation through systems ranging from cold macro-perforation to hot micro-perforation, all the way to laser.

Flexibility and reliability of Temac slitter rewinders

Often projects are developed from the outset with these requirements in mind, and the machine is therefore engineered accordingly from the beginning, but it can also happen that they need to be implemented after a few years.

Maintaining a dialogue with the customer from the moment a new need emerges allows us to provide the right support, designing solutions that best fit the slitter rewinder while meeting production targets.