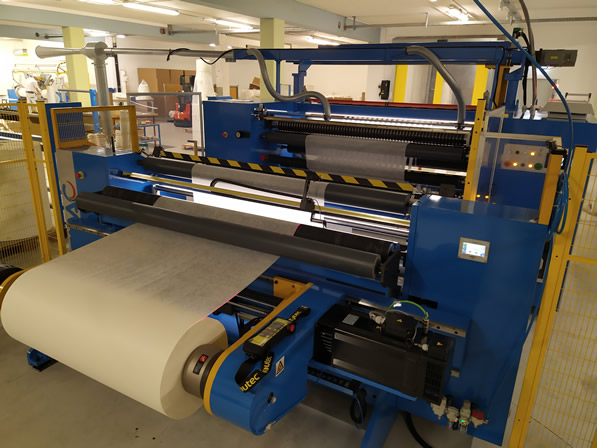

EMS 610/IS Slitter Rewinder: High Productivity with IS Layout and Full Automation

The EMS 610/IS slitter rewinder is designed for high-productivity operations: it features a machine width of 2,000 mm with a usable web width of 1,900 mm, handles parent rolls up to 1,200 mm in diameter at unwinding, and rewinds finished rolls up to 600 mm in diameter. The maximum line speed reaches 500 m/min, ensuring high performance even during intensive production cycles.

IS layout: separation between unwinder and slitting/rewinding section

This machine is supplied in the IS configuration, meaning it is equipped with an independent unwinding unit, separated from the slitting and rewinding section by a platform. The material runs underneath the platform, guided by a series of rollers and protected from floor contact by a stainless-steel tray.

The separation between the unwinder and the slitting section makes parent roll changes, slitting unit maintenance, and use of the splicing table easier and more ergonomic.

Full automation and simplified operation

The finished roll ejection system is fully automatic: at the end of the working cycle, the arms supporting the rewind shafts lower, the unloading poles (in this specific case mounted on a trolley) are engaged, and the rolls are pushed by a movable plate off the shafts and onto the trolley poles.

This automatic system, controlled via the onboard computer, significantly simplifies and reduces the operator’s workload.

Customisation on demand: solutions designed around real needs

The standard configuration of our machines includes a side unloader SF12; in this case, however, the customer specifically requested the trolley shown in the video, which was custom-designed and built.

This is where the true value of customisation emerges: every customer is a key partner, as many of the most appreciated improvements stem from real production needs. Sometimes these involve minor adjustments (more practical unloading, an added ergonomic detail, or an operator-friendly adaptation), while in other cases they require more substantial engineering interventions.

Our approach remains the same: we listen to the requirement, assess technical feasibility, and transform it into a concrete, integrated, and functional solution tailored to the customer.

Automatic tail fixing with liner recovery

The real innovation of this machine lies in the automatic tail-fixing system, as shown in the video. It consists of a taping unit that applies double-sided adhesive tape to the finished rolls and features an automatic liner recovery system.

The applicator head operates horizontally on an application table equipped with two full-width transverse clamps (cross direction), designed to keep the material (in this case nonwoven fabric) as stable as possible during tape application.

Double-sided tape application: stable material, stress-free strip

During tape application, the nonwoven material is also kept under tension in the machine direction, preventing transverse wrinkling on such a lightweight material.

As a result, the double-sided adhesive strip is applied without transverse stress on the web.

Integration and control: EtherCAT communication

The applicator head is connected to the machine PC and communicates via the EtherCAT protocol. This means the taping unit does not operate independently but is fully integrated into the central control system of the slitter rewinder: it receives real-time commands, sends back status and process signals, and synchronises with the other machine functions throughout the production cycle.

EtherCAT, designed for high-performance industrial applications, ensures fast and reliable communication between devices, reduces latency, improves diagnostics, and simplifies technical service through more accurate control and feedback.

Maximum flexibility: tail closure on any slit width

Automatic tail closure can be used on any web width, thanks to a system with a through-beam optical sensor (photocell / material / reflective strip) that automatically detects whatever slit width the customer is running.

To allow tape application, the machine stops in torque mode at “zero” speed, keeping the material under tension and pausing the process at a predefined distance before reaching the set target length. This allows the final length to be reached with the tails closed at the exact position.

(This distance can be adjusted by the user to fine-tune the position of the closing tape on the finished rolls.)

Once the application is complete, production resumes immediately, while the applicator head returns to its start position ready for the next cycle—optimising cycle times by keeping the pause state limited strictly to the time required for tape application.

Stability, precision, and rewinding quality

The EMS 610/IS slitter rewinder is designed for customers seeking productivity and continuous operation: medium-to-large manageable diameters, speeds up to 500 m/min, and an IS layout that separates unwinding from slitting/rewinding for faster and more ergonomic roll changes and maintenance.

Automatic unloading reduces operator effort and speeds up end-of-cycle operations, while the ability to customise solutions—such as the dedicated trolley—demonstrates the flexibility of the machine concept.

Completing the system, the automatic tail-closing unit with double-sided tape application and liner recovery, fully integrated via EtherCAT, ensures more stable, precise, and uniform finished rolls, even on lightweight materials such as nonwovens and across any slit width—optimising both processing time and final product quality.